Truly, community gardens are beautiful, peaceful places that allow us to connect with nature and our neighbors. That’s why The BioEnergy Project presentation for the ISC Research Symposium at UCSD caught my eye. It’s an Agrobiology project to support local healthy food sources by diverting organics waste from landfills.

Enid Partika, Zachary Osborn, and Andrew Liedholm are an environmental chemistry grad student, a biotechnologist, and a computer science grad student who form The BioEnergy Project team at the University of California, San Diego. They are working to bring a successful, small scale food waste recycling system, developed in the Rogers Urban Farm Lab, to campuses, community spaces and homes. Much thanks to them for sharing with the Labconscious community!

The Digesterponic System is easy, efficient and affordable, organics recycling technology that upgrades typical composting

1. What problem does the Digesterponic system solve?

It makes food waste recycling achievable and affordable for non-experts. The majority of food waste comes from residential streams. Most cities in the United states aren’t equipped to handle large scale food waste for composting. It takes a lot of start-up capital, government subsidies and assessments to get large scale regional projects off the ground. A single farm scale digester system can cost one million dollars. Meanwhile, our smaller scale system allows people to quickly be able to reap the benefits of fertilizing a high growth crop and produce a little biogas energy too.

Sadly, 133 billion pounds of food waste are thrown away in the United States every year, resulting in food waste being the 3rd largest emitter of GHG as a country, and being a main contributor to filling landfills. Meanwhile, 1 in 9 Americans are food insecure without access to affordable and nutritious food. Regulations such as AB 1826 and SB 1383 in California will be making organics recycling mandatory for businesses in the next few years, and waste hauling regulations across the country are forcing waste haulers to travel across state lines just to get rid of their organic waste. Digesterponics can tackle this food, climate, and energy trilemma with a single affordable product that localizes organic waste disposal, food production, and energy generation

2. Who can use this system?

Initially we expect the early adopters will be environmentally conscious people who want to do their part. The system can be used by one person, a family or a community garden group. University dining or high-end restaurants with compact, seasonal hydroponic gardens could take sustainability further by adding the Digesterponic System. Community gardens would attract people who come to drop off food waste to take home vegetables. Our team would love to partner with non-profits to bring this system to people anywhere in the world who need of a local source of healthy food.

Our system can be easily scaled up to the production requirements of a commercial operation by simply linking tanks in series and parallel and would continuously produce a consistent 150 gallons of fertilizer per week from each community sized digester. If a company needed 3,000 gallons of fertilizer every week, then we could lease land from the farmers themselves, and construct a system of 20 sequential community digesters to meet their needs for the fraction of the cost of most digestion systems on the market today.

3. How does it work?

The Digesterponics system combines both anaerobic digestion and hydroponics technologies. Anaerobic digestion is a microbial fermentation process that occurs without oxygen and is used to convert organic waste such as yard trimmings, agricultural and municipal wastes, and food waste into biogas and fertilizer, while hydroponics is an efficient and environmentally-conscious farming technique that uses inert porous media and recycled nutrient-rich water to grow food instead of soil and flooded plains, which is commonly used in traditional farming.

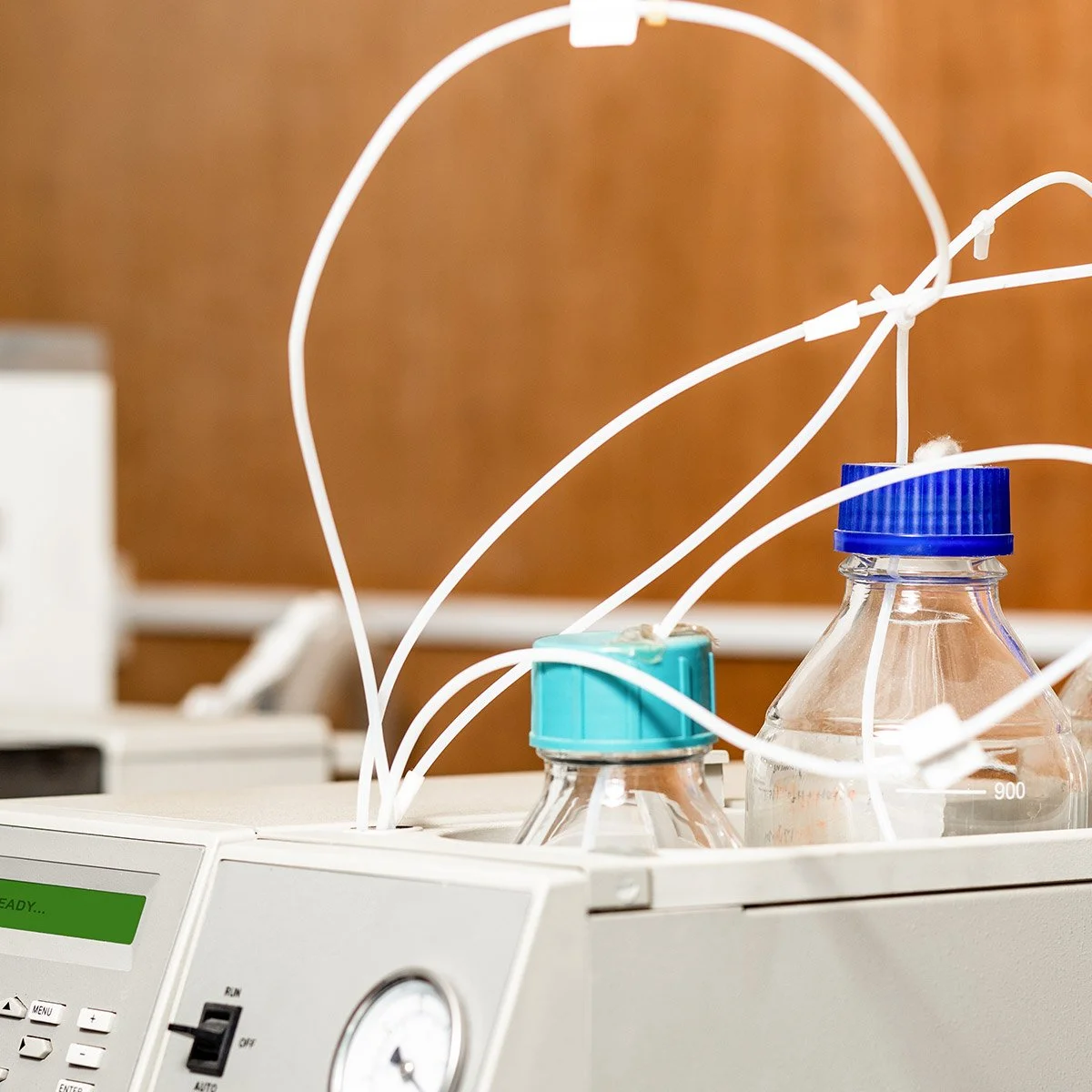

After inoculating your system with the samples we provide, you simply feed the food waste into a standard sink and garbage disposal system that automatically pumps the slurry into a series of digestion tanks that autonomously monitor and regulate the fermentation process using microcontrollers and sensors developed in-house, that you can visualize on a computer or smartphone.

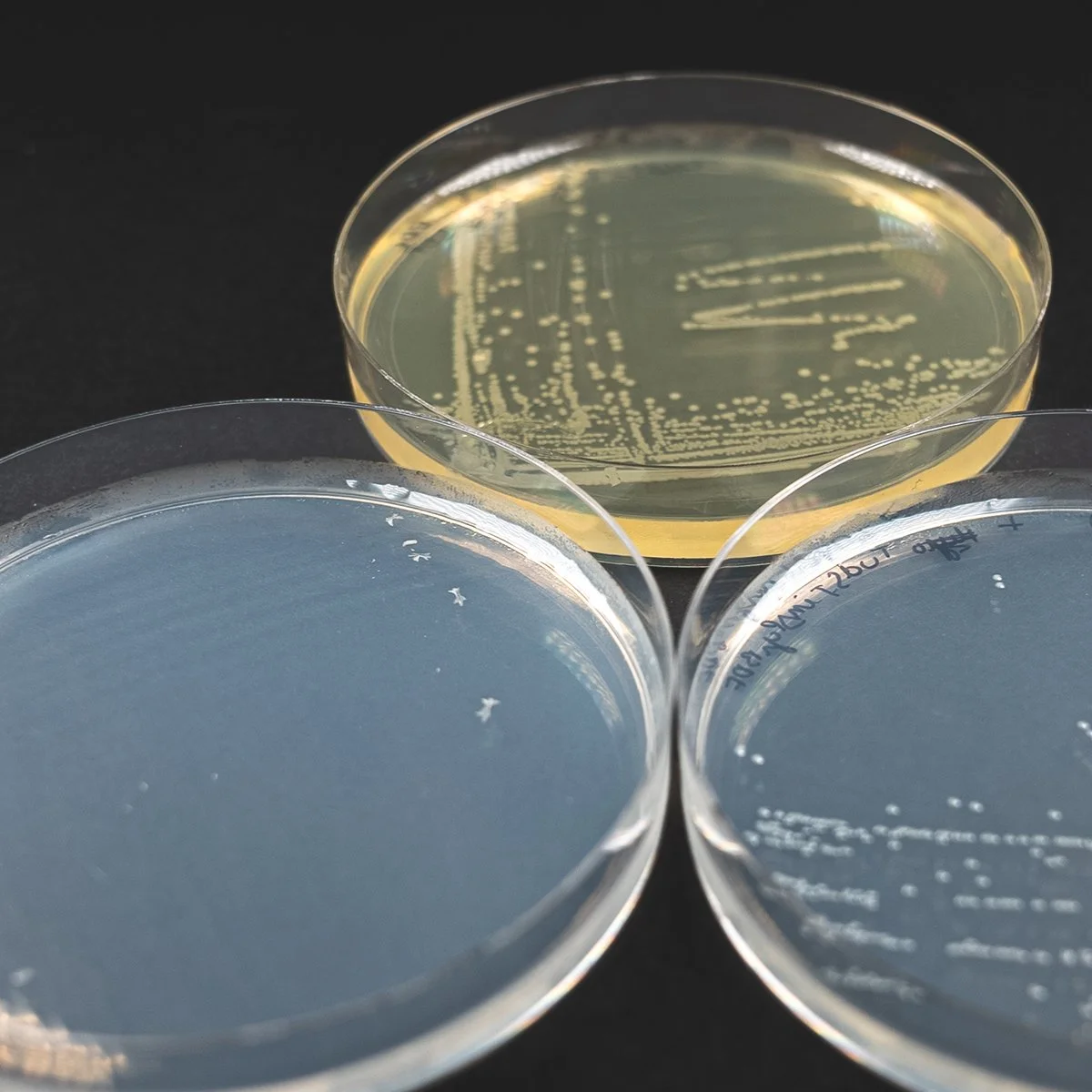

During this fermentation process, a community of anaerobic bacteria break down the organic matter in food waste (macromolecules such as proteins, lipids, carbohydrates, and nucleic acids) into smaller monomeric components such as small chain fatty acids (acetic acid) that are eaten by methanogens to produce biogas, which is mostly methane gas and carbon dioxide.

After about 30 days of initiating your reactor, your initial fermentation will be complete and you can dilute the fertilizer 2 to 1 to use in your hydroponics and grow the food of your choice! You will also be able to use the biogas the system produces in an outdoor cookstove, barbeque, or space heater.

4. What crop plants are most suited?

Greens (kale, Bibb lettuce) Herbs (basil, thyme, rosemary) and Brassica (broccoli, cabbage). The high phosphorus in the digestate makes it great for plant growth. However, there are shallow root zones limited by the depth of the hydroponics trays. We are always testing out more plant varieties on our system, so the list of plants will grow as we collect more successful tests. The start up costs for the hydroponics is higher than traditional gardening, so we focus on cultivating high value crops with shallow root zones such as basil in the summers and arugula in the winter.

5. When I investigated hydroponics, I saw that 90% of lettuce in the United States is grown with hydroponics. That surprised me. Is it correct to say that hydroponics is an optimal growth system, much better than land for growing produce?

Correct. For indoor growing in general, you don't have to deal with pests, which is a huge benefit. There's specialized lighting that you can purchase that will give the exact light spectrum that your plants are looking for. That also maximizes the growth because weather isn't a factor. Airflow isn’t a factor, since plants are evenly spaced so that eliminates diseases like powdery mildew. It's really a very efficient way to grow plants. Especially if you're pressed for space or water, it just depends on the fertilizer.

6. How does this compare to using synthetic fertilizers?

Hydroponics is precision farming that reduces nitrogen pollution. Right now, synthetic fertilizers are less expensive because of the large volumes sold. However synthetic fertilizers are not as environmentally friendly as our system.

7. What conditions are needed to run this system? I'm assuming it can only be used in summer in some climates.

The system is ideal for warm tropical climates but can also be operated in colder climates in a temperature-controlled greenhouse or with a heating element and insulation. In colder climates, the biogas may be used to offset heating costs during the winter. The system must also maintain a pH between 7.5 and 8.5, which is monitored by our smartphone and computer-connected sensors and microprocessors. If the pH is out of whack, then it can be adjusted with commercially available pH and nutrient adjustment systems

8. How does software automation improve the Digesterponic system?

It enables the user to maintain and operate the system without full time staff and without extensive knowledge in microbiology, anaerobic digestion, chemistry, or agriculture.

9. Will BioEnergy provide any guidance to users?

In addition to providing a detailed instruction manual with video clips and images inside of every package we send, we will also have Live Streams for our customers and the public. We are offering special detailed videos and 1 on 1 Q&A with members of our group. This will be accessible to a wider customer base seeking knowledge of anaerobic digestion, urban agriculture, hydroponics, and aquapoincs. We will also be offering phone and video consultations by request through our social media accounts to customers and the public. We want to encourage innovation, as well as bring back the interactive learning process that connects our minds and potential with physical accomplishments. You can view some of our live streams now! They are posted on Roger’s Community Garden YouTube Channel.

10. Are replacement parts specialized, and if so are they available?

Replacement parts are readily available at Home Depot, US Plastics, Uline, and most local hardware, tote, and hydroponics stores. Some biogas equipment is specialized and would need to be ordered through our website, Amazon, or Alibaba.

11. Are there any safety issues to consider?

Odor is controlled by carbon and biofiltering. Pathogens and plant toxicity are prevented by special aeration technology. Biogas is stored at low-pressure with relief through an airlock. Again, we send a detailed information packet and instruction manual with every product, in addition to providing live streams, instructional videos, and Q&A consultation on YouTube and Facebook.

12. How can our readers learn more?

Yes! Please visit https://www.rcgucsd.com/ to learn more about our collaboration with UC San Diego and Roger’s Urban Farmlab. Watch our livestreams on our youtube channel and follow @bioenergyproject on Instagram and The BioEnergy Project on Facebook for project updates. Or you can email for more information at thebioenergyproject@gmail.com