Did you ever stop to think about how much energy it takes to run a western blot, or how much energy that -20°C, -80°C or domestic freezer is using in your lab? I think for most of us these kinds of things just add to the white noise surrounding us as we are working at the bench. That, however, does not mean this issue is not important. Energy production is responsible for 26% of Greenhouse Gas Emissions worldwide, and laboratories are among the most energy intensive building types. In fact, labs use five times more energy per square foot compared to a typical office building. It is not uncommon to see just one large lab facility use as much energy as a small residential neighborhood!

The reason labs use so much energy is because like humans, they need to breathe. Typical labs require between 6-12 air changes an hour; every 5-10 minutes the building is ejecting its entire volume of air and replacing it with new air. Heating and cooling this amount of air so often consumes a tremendous amount of energy, anywhere from 60% -80% of the total building energy budget. Lighting, equipment, computers, servers and other plug loads constitute the remaining 20%-40%. With energy prices rising sharply across the globe, company executives are taking note of the effect of energy consumption on their bottom-line and putting company resources into reducing energy use.

Despite so much energy use, energy management opportunities are plentiful in laboratories and there are a myriad of ways to reduce energy consumption. Entire industries have sprung up around facility energy management needs from LED technology to smart HVAC optimization. In my next post we will take a deeper look into the lab space and identify energy intensive equipment and methods for reduction.

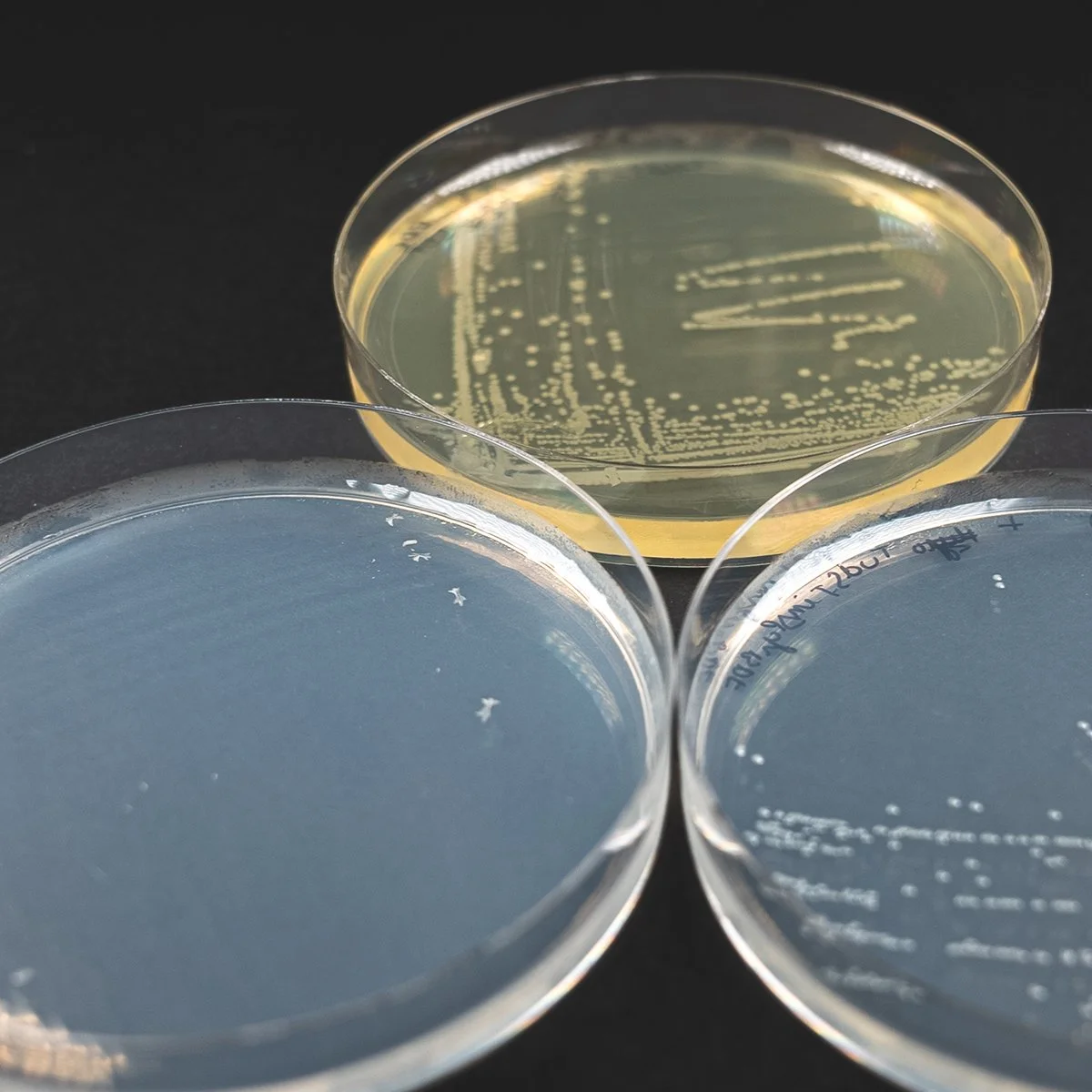

Researcher working on Western Blot results

Copyright : sinitar

Get an insider’s look at how research and clinical diagnostics are expanded by integrating software, data and robotics, as well as the opportunities “to dial” in workflows for cost and carbon savings.