The Red2Green recycling service reduces biohazard waste treatment loads and contributes to sustainability

Today's Labconscious interview is for laboratory researchers interested in an easy to use and eco-friendly red bin system. Our thanks to Ian Lanza who is a regional life science director for Triumvirate Environmental, a provider of turnkey environmental and hazardous waste management services to education, healthcare, industrial, and life sciences labs...including New England Biolabs!

1. Disposable lab consumables are often necessary to lab work. Researchers want to be able to dispose of these materials in a safe and sustainable way. How does waste minimization work, and what kinds of goals does Triumvirate Environmental help life science labs meet?

A true waste minimization effort must take a holistic approach beginning with the materials and waste generating process all of the way through final management of the waste. My team and I work with researchers and institutions to understand the waste generating process with the individuals creating the waste. The better we understand the process and the materials, the more successful we are in finding the most sustainable management method. We will try to first eliminate a waste by altering the process or changing the material. If we cannot not eliminate the waste, we will be work to classify and collect the waste in a manner that can be easily reused or recycled. With this approach we have been able to reduce or eliminate waste streams, or divert waste streams from less sustainable treatment methods (landfill or incineration) to more sustainable treatment methods (reuse or recycling).

The more progressive institutions have developed sustainability programs with teeth. By this I mean, programs with real goals and targets. Often, sustainability programs target waste management programs. My team and I have partnered with some of the largest and most innovative life science companies in the world to help them hit their waste minimization and recycling goals by starting with the waste generating process, and ending with the final treatment and disposition of the material.

2. What is Red2GReen? How is biomedical waste usually disposed of, and how does Red2Green improve on that? What lab items are eligible?

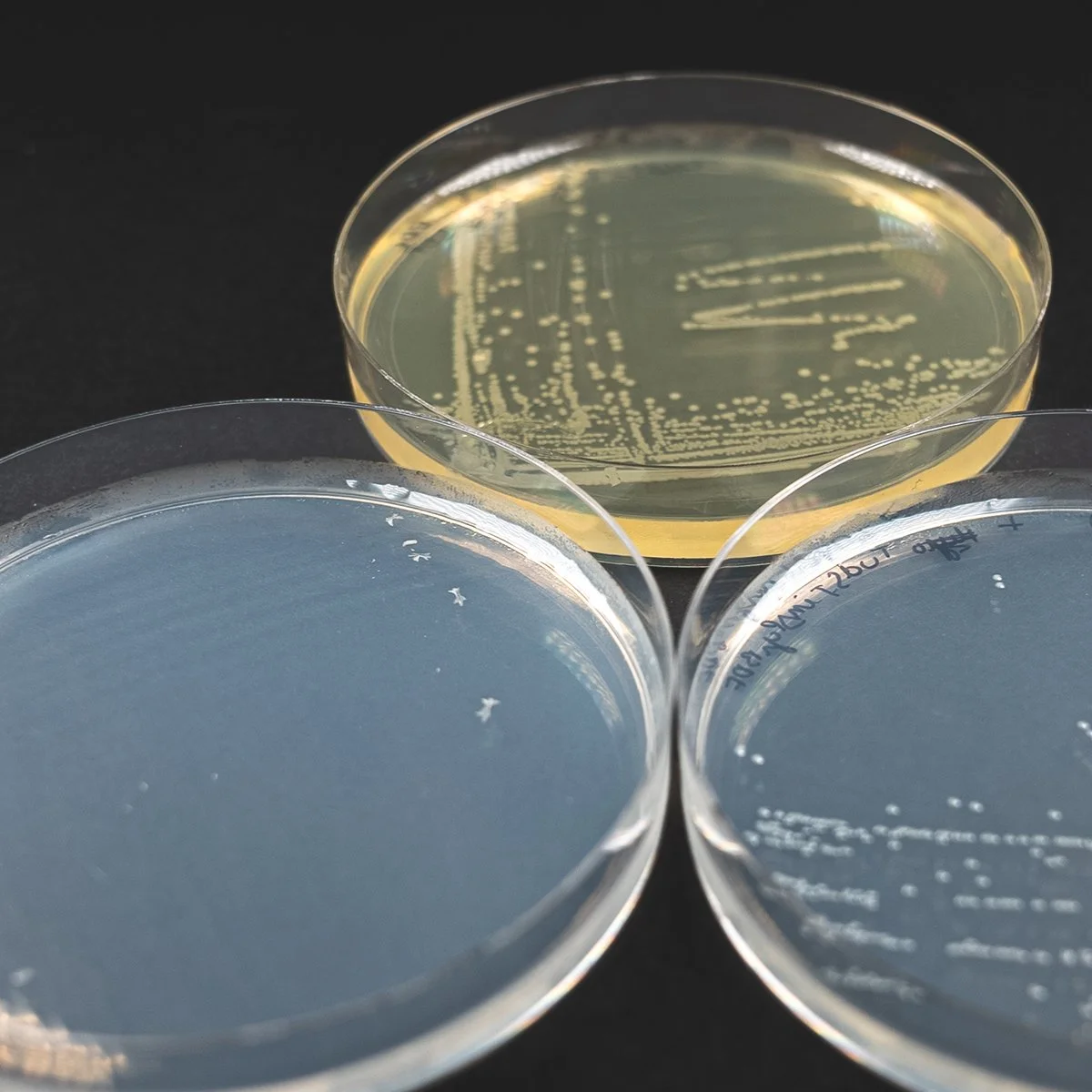

Triumvirate’s Red2Green program is the only program I know of that is recycling treated regulated medical waste. All other existing treatment processes either result in treated material being landfilled or incinerated. Both landfill and incineration pose significant environmental challenges, including green house gas pollution and water pollution. Red2Green is a true recycling program where we are taking regulated medical waste from research and manufacturing facilities, treating the waste per CDC and state approved technologies, and then sending the treated bi-product to our recycled plastic manufacturing facility. The treated material is used as an input in our recycling facility where we are making industrial grade plastic lumber. Common waste streams being captured from labs include contaminated gloves, petri dishes, roller bottles, stereological pipettes, tissue culture flasks and other biologically contaminated wastes.

We also work with some labs and bio manufacturers to source specific lab plastic. In some instances we are able to take lab plastics and send them directly to our plastic manufacturing site. We have partnered with EMD Milliporeto take many of their single use products including water filters at this facility.

3. Researchers want to support sustainability, without being distracted from their lab work. How do your services make lab recycling "user-friendly"?

My team and I work closely with researchers to understand the waste generating and collection process. In addition to understanding the process and materials, we try to understand how waste collection could be easier or more convenient for them. We try to make waste minimization and recycling easier than the current status quo. We have been largely successful with this approach. Some examples of more convenient solutions include better containers and containers placed closer to work stations.

Triumvirate also offers an onsite support service, where our staff routinely go to your site to manage the waste program. One of the goals of the service is to transfer the burden of safe, compliant, and environmentally sustainably waste collection and management from scientists to our professional staff. Our team handles a lot of the material handling, as well as serves as a compliance and sustainability resource for researchers and labs.

4. Many life science labs want to adhere to the "Principles of Green Chemistry". How does Triumvirate Environmental aim for lab waste processing that is energy efficient, enhances degradation, prevents waste and pollution?

We have a multi layered approach to developing more sustainable environmental programs in the labs. First, we are constantly investing R&D resources into developing more sustainable and efficient engineered solutions. The best example of this is the facility and process which supports our Red2Green program. We challenged the RMW treatment status quo to develop a better and more sustainable treatment process never before tried. We have many other programs or engineered solutions that result in safer or more sustainable results. Another example is our VOClok system for collecting volatile solvent waste streams. VOClok limits exposure to workers, and makes waste collection easier and safer. We then couple our engineered solutions with a hands on approach in the lab. We live in the labs at the intersection of scientific process and environmental and health programs. We work hard to understand the nuances of scientific and organization processes. This allows us to manufacture better results in the labs by altering process or material, or applying our engineered solutions in a manner that is easy for scientists.

5. Does Triumvirate Environmental assist with reporting to demonstrate the benefits of waste minimization?

Absolutely. Like any program, it is vital to articulate the impact our waste minimization and sustainability programs have on organizations. I often work with organizations to understand what their data or reporting needs may be to ensure we are providing meaningful and relevant metrics.

6. Can you give an example of a "big win" by any of your life science lab clients?

A recent Red2Green success story came from one of our big pharma clients in the area. They were treating their RMW onsite using an aging process that was causing many financial, logistical, and regulatory issues. The systems required two daily operators, and had recently caused several environmental violations. As they looked for a better way to manage the waste stream, we presented our Red2Green program. Because our process was a completely different we had to work closely with manufacturers and researchersrevamp the waste program in the labs. We worked closely with researchers to identify better waste containers and developed new work flow to ensure waste removal services linked up with their manufacturing runs. By working closely with the onsite users of the service, our Red2Green program didn’t only result in a more sustainable management of the material, but a better experience for the researchers and manufacturing technicians who generate the waste. YTD we have treated and recycled 210,000 pounds of waste, which were previously being sent to a landfill.

I partnered with New England Bio Labs several years ago to roll out our Red2Green program. With our Red2Green program we were able to eliminate cardboard from the RMW waste steam, right size the waste shipments (reduced trucking fees) and diverted over 45,000 pounds of RMW from landfill to recycling.