The US Microbead-Free Waters Act of 2015 prohibits the manufacture of rinse-off cosmetics containing microbeads from July 2017, and of their sale from July 2018. The manufacture of non-prescription drugs with microbeads is prohibited from July 2018, and their sale from July 2019. Why was this act passed, and how should it affect our thinking about the proper disposal of microspheres in the lab?

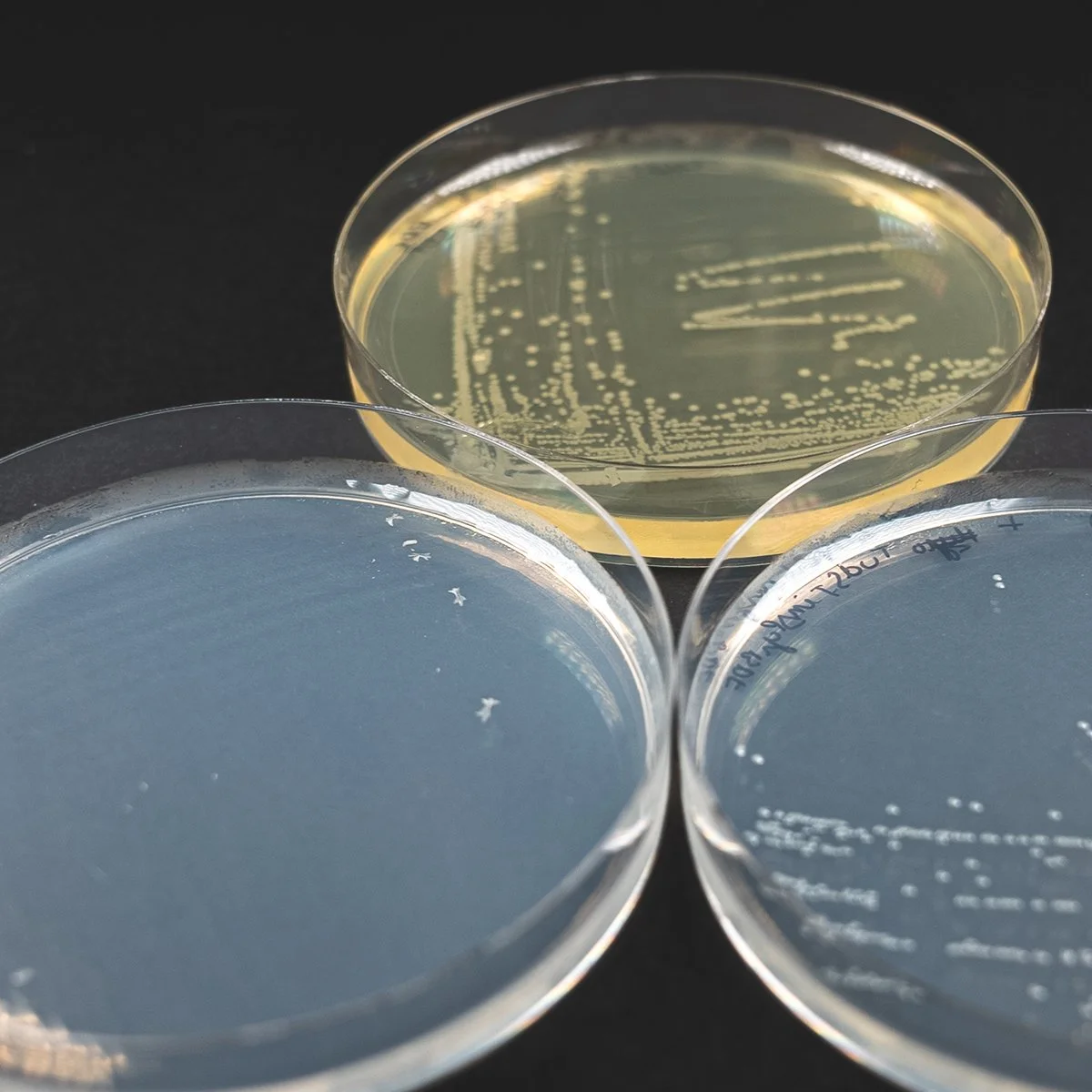

Image of PHAs bioplastics developed by Bio-on, from their web site.

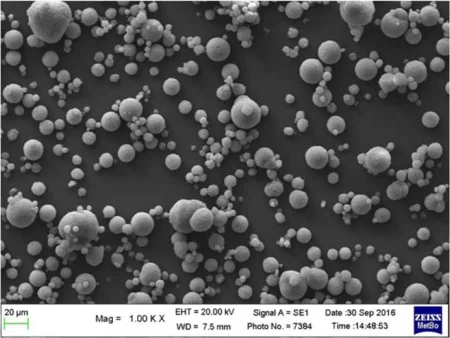

Plastic microspheres, a.k.a. microbeads, are used to great effect in many biomedical and biotechnology research applications. These synthetic plastic beads are sized 10µm to 1000µm (1mm) and generally composed of polystyrene(PS) or polyethylene(PE),. The PS or PE beads can be clear or colored, and may be linked to, or colluded with magnetic particles, or a fluorescent dye. Depending on the intended application, microspheres can also be ligand coupled to proteins, peptides, antibodies, DNA or RNA. Another common type of microspheres are made from polylactic acid (PLA), a biobased plastic, for use in clinical drug delivery studies. It would be difficult to overstate the tremendous contribution of microbead based assays to research studies and clinical applications….for cell sorting, cell separation, immunoprecipitation, protein binding and next generation sequencing procedures.

While supporting some great research applications, petroleum based plastic polymer microbeads do have some unfortunate environmental consequences. These types of microbeads do accumulate in the environment, particularly in marine wildlife. There is a problem with toxicity. Microbeads strongly attract organic pollutants like DTT and PCBs, while leaching plasticizers. Plastic microbeads are building up in marine life tissues, and can move up the food chain. Hence the cosmetic products ban.

As an aside, biobased and non plastic microspheres used in some research applications have very different physical properties. PLA microbeads are “biodegradable” inside the body – but PLA is not known to degrade very well in the environment. Non plastic microspheres include cellulose, gelatin and silicone based microbeads. These non plastics are now being targeted for use by cosmetic industries as environmentally friendly alternatives.

Biotechnology companies are working to facilitate the switch from synthetic polymer plastics to non-toxic, biodegradable and bio-based plastics for use by medical and pharmaceutical researchers. Polyhydroxyalkanoate (PHA) plastic can now be produced economically in plants. For example, the company TerraVerdae Bioworks reports that they are developing PHA for use by medical and pharmaceutical industries. As well, the company Bio-on has PHA bioplastic microbeads for NMR imaging of tumors and drug delivery systems.

"Using PHA bioplastic is very advantageous," explains Prof. Mauro Comes Franchini, Bio-on Chief Scientific Advisor, "because it is safe for the patient and has no side effects. As an industrial chemist, my main goal is to work with products that are safe for the environment and human health, especially when it comes to biomedical applications. Bio-on bioplastics fully meet these requirements and open up important, unexplored fields for nanotechnologies in medicine - a rapidly growing sector." - www.bio-on.it

Perhaps if it not possible to produce environmentally friendly plastic microbeads with optimal properties for every research application….a bonding agent can be invented to encourage proper disposal of plastic microbeads as solid lab waste. In the meantime, the best solution is to not dispose of any plastic microspheres down the drain into our waterways.

Lab sustainability certification programs are learning tools to help scientists identify changes that will reduce environmental impacts and conserve resources. A key feature of these programs is that they can help research institutions reach sustainability goals without undermining the autonomy of academic lab teams. The catch is that only a minority of labs volunteer to participate. This month, I’m summarizing two recent studies that examined scientists’ perceptions of the benefits and pitfalls of using common programs and offered suggestions on how to improve them.