Wildfires are scary. Yet we know from ecologists that they also function to regenerate an ecosystem. Otherwise, debris accumulates in an old forest, leaving little space for new life. Similarly, our environment is accumulating debris from our use of traditional plastics. This plastic debris harms living things directly and indirectly through food web effects. Many chemical and biological engineers are continually working to help us out of this predicament!

Today’s blog is about (truly) bio-degradable Nodax™ PHA plastic, produced by the biotech company Danimer Scientific. Nodax™ PHA was invented some time ago, but its scaled-up commercialization has just been ignited by food industry investments. Expect this bioplastic to spread like wildfire.

A microbial harvest

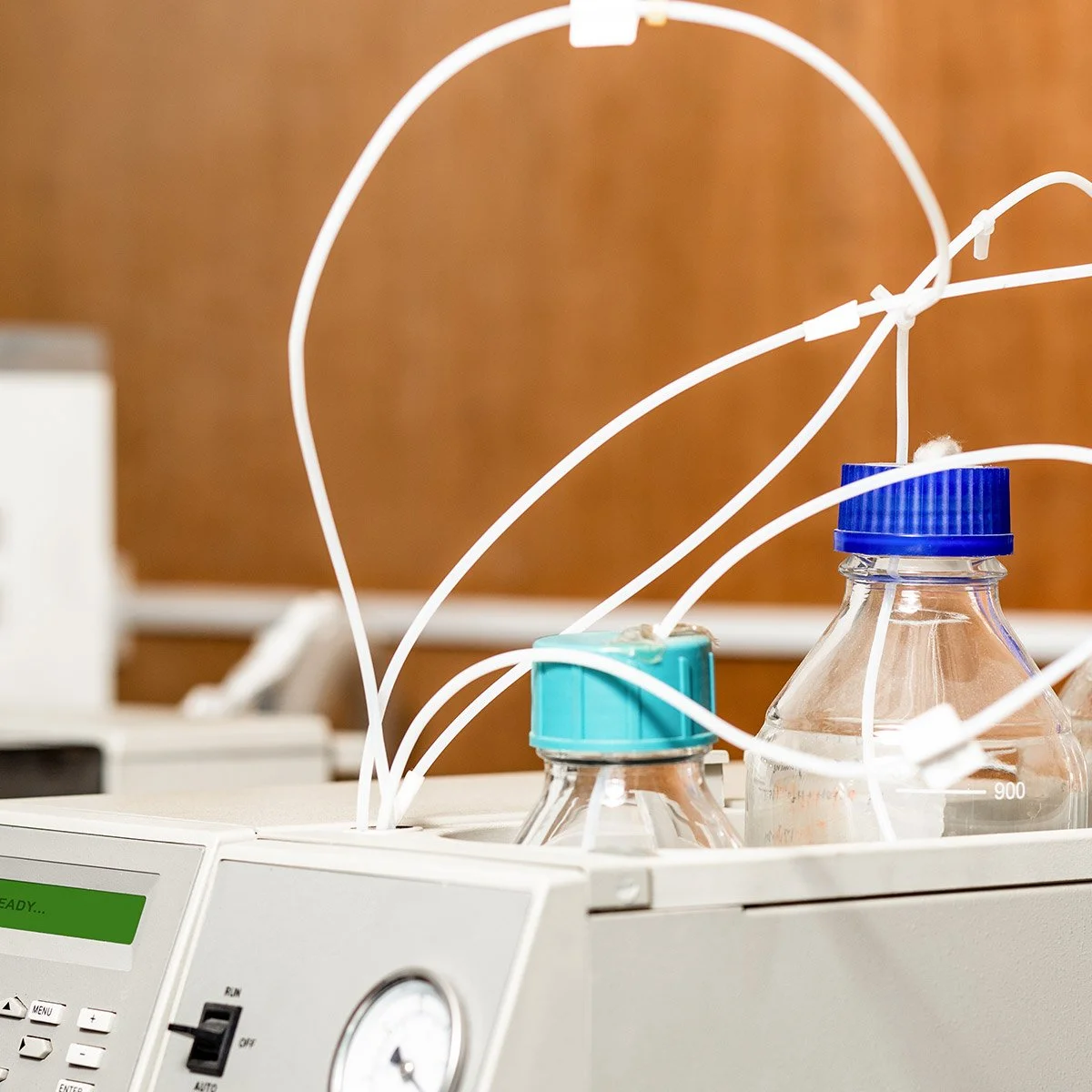

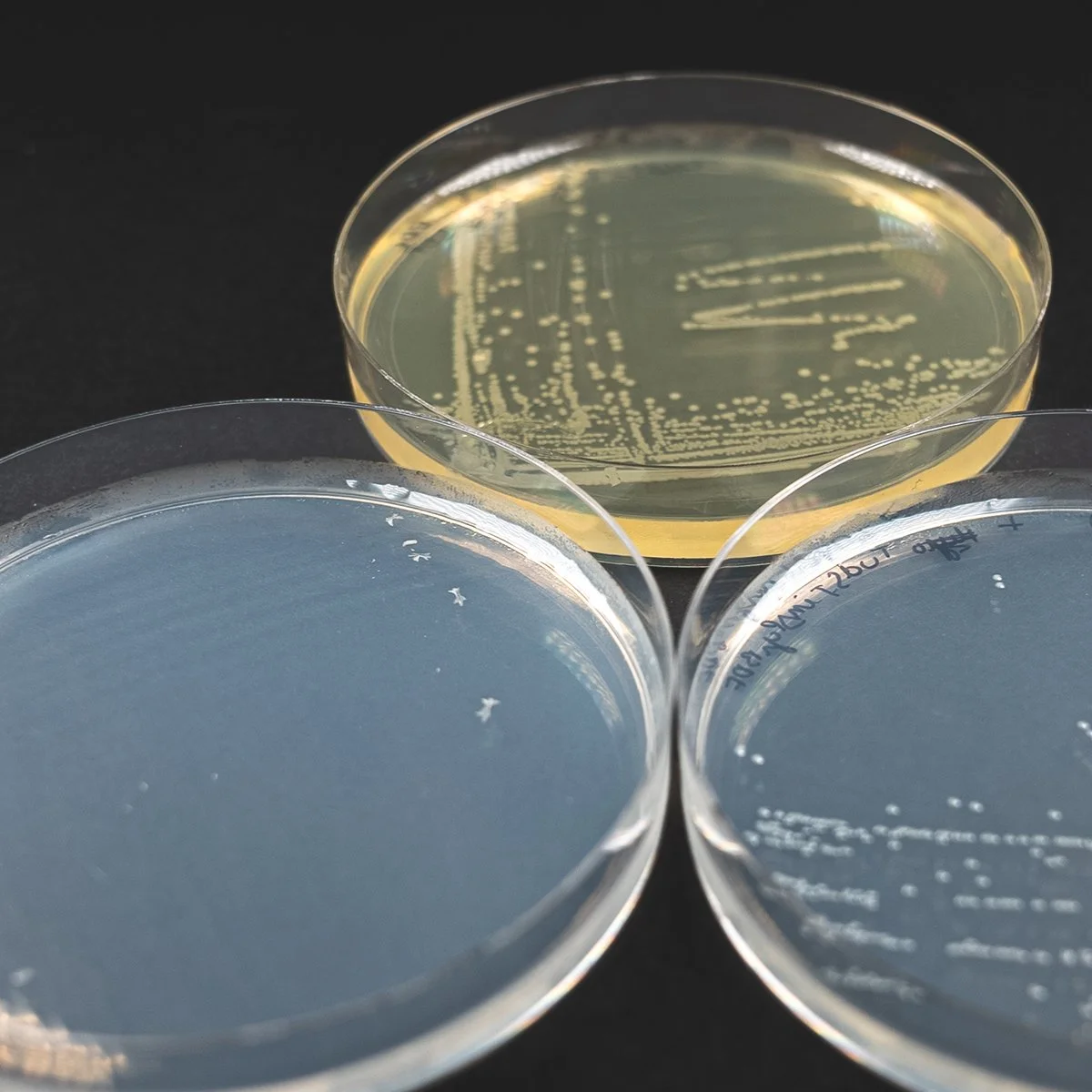

Fig. 5 Bacteria producing Nodax™ class PHA copolymers

Nodax™ Class PHA Copolymers: Their Properties and Applications. In book: Plastics from Bacteria

DOI: 10.1007/978-3-642-03287-5_10

Image credit: Full text available on Researchgate via author Isao Noda, Ph.D. Chief Science Officer and adjunct professor at The University of Delaware

Nodak™, otherwise known as PHBH or poly (3-hydroyxbutyrate-co-3-hydroxyhexanoate, is a bioplastic produced by bacterial cultures grown with canola oil as a renewable feedstock. According to a recent review in The Journal of Bioscience and Bioengineering, Pseudomonas species bacteria have been commonly used for this production method. This production method is economically advantageous, and helps with the problem of agricultural waste. Danimer Scientific’s canola oil is produced locally as a winter crop, so it does not compete with agricultural food production. The company’s toxin-free extraction and extrusion processes are cost competitive and leave almost no carbon footprint.

Commercial scale production of this resin is in process at their new fermentation facility in Kentucky. Impressively, Danimer Scientific has already partnered with Nestlé on water bottles and Pepsico on plastic packaging film! The company is open to partnerships with any brand owners searching for sustainable manufacturing or packaging, as well as conventional plastic molders.

Scientifically established functionality

What’s most exciting to the sustainability minded, is that this bioplastic is biodegradable in both aerobic and anaerobic environments. Which is different from PLA plastic that is often sourced by environmentally conscious manufacturers for its compost-ability feature. Unfortunately, not everyone has access to industrial composting service facilities. Therefore biodegradability in waterways and landfills is even more attractive.

Biodegradability of Nodax™ PHA in marine environments has been recently demonstrated by researchers at The University of Georgia New Materials Institute in their Environmental Science and Technology study. The material biodegraded by 40% over 40 days in seawater, as compared to 78% over 45 days via intensive aerobic compost. Excitingly for students and faculty alike, the New Materials Institute has also just been awarded a grant as the third site for the National Science Foundation’s Center for Bioplastics and Biocomposites, or CB2, an Industry/University Cooperative Research Center. How awesome is that?!

As far as its other features are concerned…. Nodak™ is durable with mechanical properties comparable to high-grade polyethylene and polypropylene. The resin composition can be customized and blended with other polymers for different applications. Its versatility includes fibers, synthetic paper, plastic foams, rigid blow molded packaging, heat seal-able films and latex style gloves. Although we might infer that depending on item being produced, the ultimate manufacturing might use a plasticizer. Nodak™ is biocompatible for use in tissue engineering, as a drug carrier, and useful in medical devices like sutures, screws, surgical mesh, bone implants, dental material, ear implants and orthopedic pins

Could anything in your lab be remade with Nodax™ PHA?

Bioplastics as a whole currently make up less than 5% of the total plastics marketplace. There has been investments made by industry in part because Danimer Scientific’s large scale production methods are cost comparable to petroleum based plastics. Still, it’s part of human nature to be wary of change. Lab materials in particular must be reliable. Biologists need to balance practicality with improvements to lab waste streams. The only caveat that jumps out with PHA plastic vs PLA is that PHA is soluble in green solvents, i.e. ethanol. That’s not a good fit for genomic sequencing methods..

Life scientists, please share your thoughts on good possible lab uses for this terrifically biodegradable plastic!