Life sciences laboratories are another area in which plastic waste can be reduced. Approximately 5.5 million tons of plastic waste are produced every year in life sciences laboratories alone, including items like pipette tips, nitrile gloves and cell culture flasks. In the age of global waste pollution and the ubiquity of plastic in the world around us, this is definitely too much. It can’t all be changed, but improvements are possible in some areas.

All around the world, more and more plastics are being produced and end up unchecked in the environment. Images of beaches covered in rubbish and the giant garbage patches in the world’s oceans full of disposable plastics and consumer products have shifted these problems into mainstream focus. High time for life scientists to take a look around their own laboratories as well and ask what each individual can do to reduce the waste mountain of 5.5 million tons that is generated every year by life sciences laboratories alone [1].

Of course, the use of plastics is justified by their excellent properties for use in life sciences, such as resistance to solvents and chemicals, the (usually) lower manufacturing costs, low weight and the almost infinite range of ways in which plastics can be adapted to the desired application area. On the other hand, we have to ask ourselves whether a laboratory really does need to produce several waste bags full of consumables every day, including cell culture flasks, pipette tips, lab gloves and packaging. What can we replace, how can recycling be used in a meaningful way, and what solutions are available for the future?

The following article provides an overview of how small changes in the day-to-day laboratory environment, the use of alternative products and other ideas can help us all reduce our footprint. If you would like to calculate your own footprint, you can do this with the iGEM Goes Green GHG Emissions Calculator [3].

The three Rs – Reduce, Reuse, Recycle

The three Rs strategy — reducing the amounts we use, reusing items and recycling them — can really be applied to all walks of life, so why not in laboratories as well? Admittedly, it is a challenge in this environment, but it is not impossible. Many people and organizations have already given a lot of thought to the topic. So, as an addition to the original three Rs, here are R numbers 4 and 5: Rethink & Replace.

Reduce — minimizing consumption of plastic

A high proportion of plastic waste is generated by disposable, single-use products like pipette tips or reaction tubes. Of course, these products are indispensable in the day-to-day workings of a modern laboratory, but there are options for reducing the consumption of resources here.

When designing a product, manufacturers can pay attention to a resource-efficient design, production and packaging. By doing this, quite a lot can be achieved even for such a seemingly everyday product as a pipette tip. For example, the company Starlab introduced a special injection molding technique that allows them to manufacture their Tipone pipette tips with thinner plastic walls — without any compromise in terms of quality. After all, what use to the user is a more “eco-friendly” product if it fails to meet the requirements? The new technique uses up to 40% less polypropylene (PP) per pipette tip.

Not only this, but the design of the pipette tip racks and the refilling system also ensures that less material is used. Over the course of a year, this adds up to more than 25 tons of PP — in total, more than 125 tons of PP has been saved in the production of racks and pipette tips since the new production methods were first introduced. Despite the reduction in the amount of material used for the pipette tip racks, these components have retained the same level of robustness and the same suitability for autoclaving. According to Starlab, the excellent autoclaving performance means that the racks can be reused several times with the aid of a refilling system — with no loss in quality [4].

The company has already been offering practical, non-sterile refilling units for Tipone tips without filters for 20 years. However, particularly delicate applications require the use of filter tips, especially in cases where it is important to avoid aerosol cross-contamination. To meet this demand, Starlab developed sterile refilling units for filter tips some time ago, which are easy and safe to use. These are very popular, as they help to avoid contamination during the refilling process.

Other companies are also looking at similar options: the Californian company Labcon reduced the plastic share in its pipette refilling systems and swapped the plastic outer packaging for recycled cardboard [5]. New England Biolabs has reduced the use of plastic in its molecular biology kits for DNA purification by up to 44% by introducing plastic flasks and columns with thinner walls [6]. This is a very simple way to reduce consumption of materials and costs in the lab.

But — no waste at all is certainly the best kind of waste. For this reason, another issue alongside careful product selection is the use of good inventory and ordering management to help avoid duplicated orders and single orders that are not really necessary. Group orders help to reduce delivery costs and save resources by avoiding unnecessary delivery miles — and, where appropriate, the larger packaging sizes reduce associated packaging waste. Anyone who would like to keep a digital overview can choose from a range of Inventory Management Tools, some of which are available at no cost. And there is potential for savings when it comes to the actual “manual work” on site. In cell and molecular biology labs, it e.g. already helps to calculate the minimum number of reaction tubes and prepare master mixes [7]. This not only reduces the number of reaction tubes and pipette tips, but also the time expended.

Reuse — wherever it is possible

In many life sciences laboratories, plastic materials are increasingly replacing glass and other materials: with single-use inoculation loops made of plastic instead of stainless steel, single-use Erlenmeyer flasks or single-use Pasteur pipettes made of plastic — the list goes on, and we could add many more products. Single-use, disposable products provide sterility and save time — on the one hand. But on the other hand, they are one of the biggest driving forces behind the increasing amounts of waste being produced, including the packaging that needs to be added for every product. We must therefore ask ourselves where the use of single-use products makes sense, and where it can be avoided.

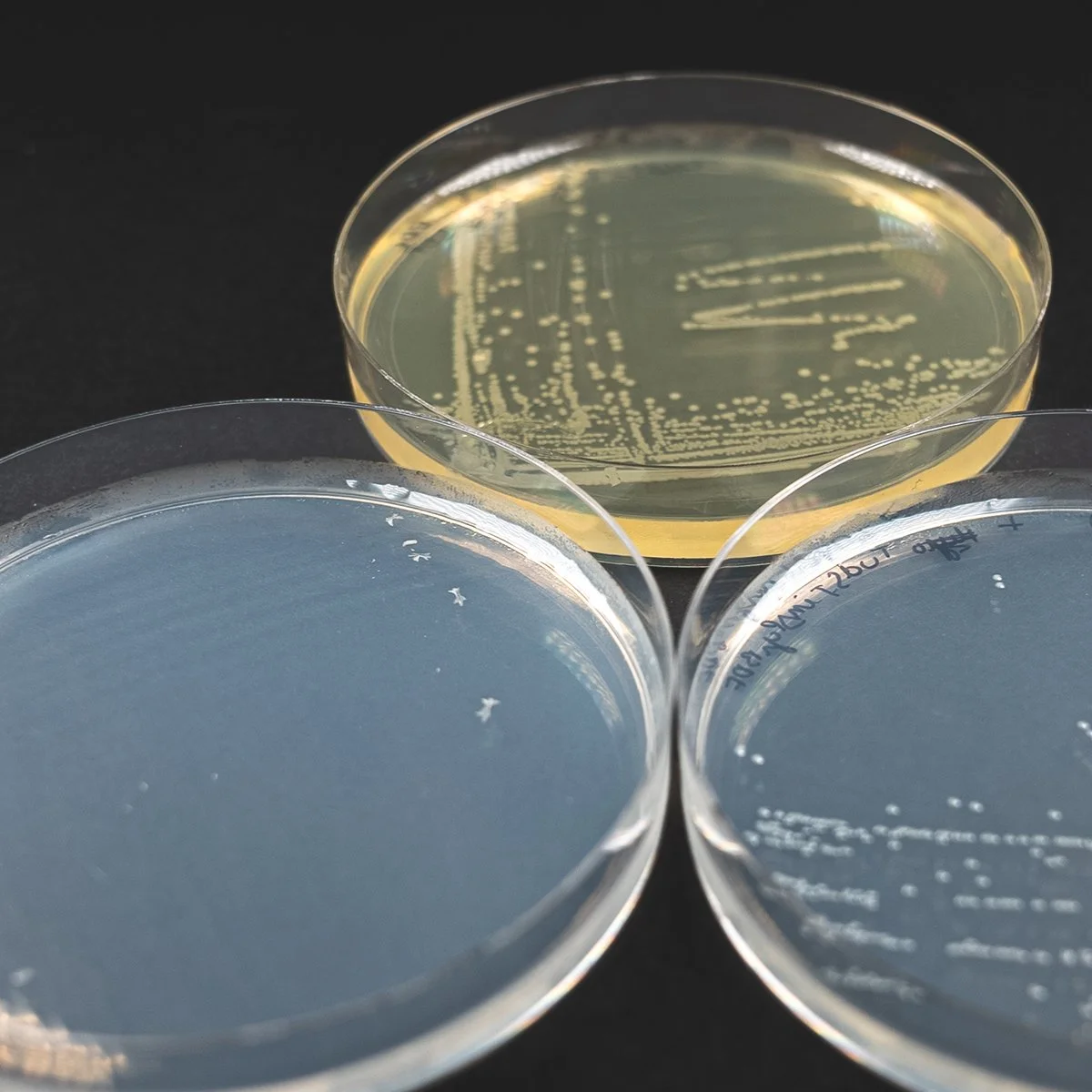

Pipettes and Erlenmeyer flasks made of glass have a longer service life and can be cleaned and autoclaved in laboratory washing machines or UV-sterilized. The same applies to Petri dishes etc. Here, an about-turn to restore working practices that favor increased, expedient reuse of glass and other materials would not only offer environmental benefits, but would also relieve the pressure on research budgets.

The US company Grenova Solutions has taken a different approach. They have developed a special washing device that rinses pipette tips so that they can be reused. Although this may initially sound like a strange idea, it does actually appear to be a genuine alternative on closer inspection. Researchers at the Center for Disease Control and Prevention in the USA [8] use slightly more than 11,000 pipette tips per week for a single method in high-throughput screening. 60% of these are used just to pipette solvent. These pipette tips were put through several washing stages, ultrasonic treatment and then UV-sterilization, after which they could be reused without any issues whatsoever. They displayed no contamination or soiling, no loss of quality in terms of the shape and materials, and the dimensional accuracy during pipetting remained within the tolerance limits. Overall, it was possible to use the pipette tips ten times in a row, reducing levels of pipette tip waste by a half. Based on their own estimates, this has meant savings of around USD 24,000 in a single year.

This approach could be worth considering, particularly in high-throughput screening and anywhere else where large numbers of pipette tips are used for buffers or solvents. According to the manufacturer, it is even possible to reuse pipette tips that have been used for e.g. PCR experiments or for transferring serum or plasma samples [9, 10].

Recycle — why not in the lab as well?

In Germany, it is perfectly normal to separate waste into different garbage containers so that it can be recycled — “green” bins, bins for paper/cardboard recyclables, and yellow waste bags for recyclable plastics. The situation is often different in the lab, where plastic waste is not always recycled and instead ends up in the general residual waste, which is then burned in a waste incineration plant so that the resulting energy can be used in downstream processes. For potentially contaminated single-use products like reaction tubes, cell culture dishes or pipette tips, this makes sense from the point of safety considerations and is a legal requirement.

But many uncontaminated products, which are also made of unmixed, high-quality plastics, could be sorted out from the waste without any problems and then recycled. These valuable raw materials are irretrievably lost when waste is disposed of using incineration methods. The following cases are examples that show a number of alternative possibilities:

Take-backs for recycling of sorted, single-type materials: pipette tip racks that are made of a single plastic, e.g. PET or PP, and are not contaminated, can be disposed of as “yellow waste” in Germany. Companies like Starlab make it even easier by offering customers a dedicated take-back service for all racks made of single-type, high-quality polypropylene [11]. These are collected and either given back out to customers to use with the refilling system, or sent to a disposal firm for recycling, e.g. in the UK. Although it is technically not yet possible to manufacture new pipette tip racks from the PP taken from old racks, recycled polypropylene can be found in many durable products, such as, pallets or garden furniture [12].

Lab gloves: According to a waste management audit at the University of Washington, lab gloves can account for around 23% of the total lab waste that needs to be disposed of [13], and particularly in cell and molecular biology labs scientists often use several pairs in a single day. However, many of the gloves that are used and thrown away are not contaminated and could easily be recycled. For this reason, Lisa Anderson — a PhD student at UC Davis — launched an initiative for recycling nitrile gloves. After just one year, a total of 2.2 tons of lab gloves had been recycled [14]. She took advantage of the takeback program offered by Kimberly-Clark [15], under which nitrile gloves can be returned and recycled — and this program is also available in Germany. The recycled plastic is then used to manufacture transport crates or park benches [16].

Products with recycled plastic materials: Take back programs and recycling are not the only option — the reverse path is also possible. Some manufacturers use recycled plastic in their products, thereby reducing the use of raw materials and resources. It goes without saying that this is only possible on lab products that do not have the highest quality requirements, for example laboratory flasks [17] or reaction vessel stands [18].

Despite the take back programs, recycling of single-type plastics and the development of products with a certain proportion of secondary raw materials, downcycling still dominates as the main method of waste disposal. In order to arrive at a genuinely closed, circular economy of the type described by the “cradle-to-cradle” approach, we need to develop corresponding materials that are fully capable of being recycled and allow us to manufacture a product of the same quality again from all the waste we collect. The EU is attempting to promote this approach with its “Strategy for Plastics in the Circular Economy” [19]. Key issues here include the support for and promotion of recycling-friendly designs and the production of environmentally friendly plastics.

Rethink: Are biodegradable plastics a solution?

In the past, a number of individual approaches for the development of biodegradable single-use products have also been presented in the life sciences sector, but none of them have been able to really establish themselves [20]. The necessary times required for these products to decompose cannot always be met in industrial composting plants, and according to the German Federal Environment Agency (UBA), even when these times are met the process does not represent a useful and meaningful disposal practice, as it only produces CO2 and water [21]. Materials recycling would be a meaningful alternative, but this is technically difficult to realize at the moment [21].

Another alternative is bio-based plastics, i.e. “classic” polymers like polyethylene, which are made from renewable resources and represent a more promising solution. Some products based on “bio-PE” materials can already be found in the life sciences sector, such as laboratory flasks [22] or the base of pipette tip racks [23,24].

An assessment produced by the German Federal Environment Agency in 2012 arrived at the conclusion that foils made of bio-polyethylene (bio-PE) on the basis of Brazilian sugar cane have a lower impact and burden in terms of climate change and the use of fossil resources than fossil PE from European production [21]. On the other hand, the bio-based plastic places a higher burden on the environment if we take the sugar cane cultivation into account, and it leads to increased acidification of soils and oceans. This means that the resulting picture is still mixed at the moment, and it is necessary to investigate separately for each type of plastic and raw material whether this production variant is better in ecologic terms.

However, according to the study by the German Federal Environment Agency, the future most probably does lie in the use of bio-based, classic plastics, such as bio-PE, since existing recycling strategies can be exploited here, allowing the overall eco balance to be improved. Secondly, a future shift toward increased use of secondary raw materials (such as residual waste materials) instead of cultivated biomass like sugar cane, which needs to be grown specially, can also have a positive impact on the eco balance [21].

Replace – what else can we do?

Thermo boxes made of polystyrene are often used in the transportation of refrigerated products, and in some cases they are also taken back and reused. There are now also a number of alternatives that use natural pulps or agricultural waste such as straw as the insulation material [25], one example being the “Landbox” from Landpack. The refrigeration hold times are comparable to thermo boxes made of polystyrene [25].

The US company Ecovative has used the fungus mycelium to coat forestry waste products like wood chips, which are held together when the fiber-like parts of the mycelium fungus mix together with the wood chips, and the resulting compound also displays temperature-regulating properties [26]. In an attempt to develop this method further, a group of students at Leuphana University Lüneburg is currently researching a fungal-based insulating material that can be produced solely from regionally procured waste [27].

Many small steps combining to achieve a great effect

Rethinking our use of plastic products and making sure they are used sensibly, pursuing active recycling strategies and constantly looking out for alternatives — a mixture of the three Rs — Reduce, Reuse and Recycle — can already help to reduce waste. This not only saves space, but also disposal costs and helps the environment. Whether the “zero-waste” laboratory will ever become a reality in the future is probably an academic point for now – but people are working on this as well [28].

Sources and Links:

[1] Urbina M A, Watts A J R and Reardon E E 2015 Nature 528 479

[2] Geyer R, Jambeck J R and Law K L 2017 Science advances 3 e1700782

[3] http://2017.igem.org/wiki/images/a/aa/T--TU_Dresden--GHG_emissions_calculator.xlsx

[4] https://www.starlabgroup.com/DE-de/sldocument/download/344900_1

[5] http://www.labcon.com/productdesign.html

[6] https://international.neb.com/monarch/monarch-nucleic-acid-purification-kits

[7] https://bitesizebio.com/25950/reducing-lab-waste-one-experiment-at-a-time/ (abgerufen am 15.10.2018)

[8] https://www.eventscribe.com/2017/posters/slas/SplitViewer.asp?PID=NzExNDU4NTEwNA

[9] https://www.grenovasolutions.com/wp-content/uploads/2017/06/TipNovus-PCR-Validation-Results.pdf (abgerufen am 19.09.2018)

[10] https://www.grenovasolutions.com/wp-content/uplo (abgerufen am 19.09.2018)

[11] https://www.starlabgroup.com/DE-de/pipettenspitzen/tipone-pipettenspitzen_WebPSub-155869.html (abgerufen am 23.10.2018)

[12] In dieser Broschüre wird das Recyclingschema erklärt (exemplarisch für das System in UK): https://www.sheffield.ac.uk/polopoly_fs/1.124891!/file/STARLAB-RecyclingBrochure-Update-Jul-11.pdf

[13] University of Washington Lab glove recycling delivers results https://green.uw.edu/blog/2016-07/lab-glove-recycling-delivers-results (accessed 20 Sep 2018)

[15] https://www2.kcprofessional.com/brands/kimtech/rightcycle

[16] https://www.terracycle.de/de-DE/brigades/einmalhandschuh-recyclingprogramm

[19] EU-Kommission 2018 COM/2018/028: Eine europäische Strategie für Kunststoffe in der Kreislaufwirtschaft

[20] https://www.the-scientist.com/careers/life-scientists-cut-down-on-plastic-waste-64547

[21] Umweltbundesamt 2012 Untersuchung der Umweltwirkungen von Verpackung aus biologisch abbaubaren Kunststoffen (Dessau-Roßlau: Umweltbundesamt)

[22] https://www.buerkle.de/website/var/assets/catalog/de/2018/html/162/ (abgerufen am 24.09.2018)

[23] http://www.labcon.com/productdesign.html (abgerufen am 24.09.2018)

[24] http://labcon.com/downloads/Labcon2018recycleguide.pdf

[25] https://landpack.de/produkte/isolierverpackung-aus-stroh (abgerufen am 24.09.2018)

[26] https://shop.ecovativedesign.com/products/mycofoam-cooler-box-lid (abgerufen am 24.09.2018)

[27] Leuphana Universität Lüneburg Studentisches Forschungsprojekt: Pilzmaterial als innovativer Dämmstoff:https://www.leuphana.de/news/meldungen-forschung/ansicht/datum/2018/08/24/studentisches-forschungsprojekt-pilzmaterial-als-innovativer-daemmstoff.html (abgerufen am 24.09.2018)

[28] Empresa Brasileira de Pesquisa Agropecuária Reducing scientific research waste production: Can we recycle lab plastics for 3D printing? https://experiment.com/projects/reducing-scientific-research-waste-production-can-we-recycle-lab-plastics-for-3d-printing (accessed 24 Sep 2018)

[29] Jambeck J R, Geyer R, Wilcox C, Siegler T R, Perryman M, Andrady A, Narayan R and Law K L 2015 Science (New York, N.Y.) 347 768–71

[30] Lebreton L et al 2018 Scientific reports 8 4666

[31] Barnes D K A, Galgani F, Thompson R C and Barlaz M 2009 Philosophical transactions of the Royal Society of London. Series B, Biological sciences 364 1985–98

[32] https://act.mygreenlab.org/about.html

[33] http://2017.igem.org/Team:TU_Dresden/iGEM-goes-green/Resources#guide

[34] http://www.labconscious.com/green-lab-supplies-and-lab-equipment-guide/#lab-waste/

[35] https://www.mygreenlab.org/

[36] http://niub-nachhaltigkeitsberatung.de/index.php/dienstleistungen-niub

[37] https://www.b2bseminare.de/alle-seminare/forschungs-und-laborprozesse-nachhaltig-ausrichten--ihr-weg-zum-green-lab

* This article originally appeared in Lab Worldwide and is re-posted here with permission from Dr. K. Hermuth-Kleinschmidt: NIUB-Nachhaltigkeitsberatung, 79112 Freiburg, Germany