Tapping an invisible potential to go green

There is an invisible obstacle to running an environmentally responsible laboratory. It’s something that is easily forgotten, easily dismissed, or even totally unrecognized. Since it is relatively inexpensive and intangible it appears immaterial to pollution. None the less it contributes to the surprising fact that pharma emits more greenhouse gases than the auto industry. Have you guessed yet? The invisible obstacle is saving electricity.

Scientists can get advice for reliable results and prompt financial incentives to save energy in labs

Steve Miller manages the High-performance Lab Initiative at energy company Eversource, the 2020 “top energy efficiency performer” in the United States. He also chairs the Electric Utility Support to Labs Working Group for the International Institute for Sustainable Laboratories (I2SL) and has fostered a Cambridge Massachusetts based Sustainable Lab group alongside MIT Green Labs Program Coordinator, Jennifer Ballew. Labconscious thanks Steve Miller for the following interview on how he helps to improve the way that life science labs work!

What is the most important thing that you want scientists to know about your role?

I’m not here to interfere with your science. I’m not a scientist. My role is never to impede your good work. My role is to enhance it if I can. Also the energy efficiency program uses public funding that you can take advantage of. It's money available to you!

What kind of guidance do you provide to labs?

We are here to help. Laboratories are a complex building type that haven’t been actively mined for opportunities until recent times. I start out by listening, asking “How can I help? What goals do you have? What have you thought about doing? What have you thought about not doing?” To borrow a line from Allison Paradise, when she does orientations for My Green Lab,... “We are here to ask why, but better yet, we ought to ask why not.” It communicates the crux of the goals while considering lab safety and productivity. We talk about how we can optimize fume hoods and plug loads given the nature of the lab work being done.

Why do scientists focused on biomedicine, ecology or biotechnology care about energy usage in their labs?

When I started out exploring energy efficiency solutions in labs, I found that energy efficiency as a stand-alone topic was not resonating within the research or commercial pharma community. When you expand that conversation to include sustainability, in which energy efficiency plays a key role, that resonates.

Scientists understand data. They understand the impact of climate change. They know that the environment they work in is energy-intensive. Lab spaces use three to five times the energy per square foot than any other commercial building. Generally, the reception is pretty good when scientists know that it’s about the environmental impact.

What is the primary driver of energy usage in most lab facilities?

Air changes per hour. You bring outside air in, condition it, humidify it, and send it in to the lab space in whatever condition the lab requires. That air is then sent back outside, and sometimes that is happening through hoods.

The air changes are really important from a safety perspective. What we do, is to try to understand the airflow requirements for the science being done. We look at how the air changes are set. Sometimes the setting is from last year, sometimes it was set 10 years ago. We ask, “Does the setting still make sense?”

The big animal in the laboratory is airflow management. Freezers from an energy perspective are pretty intensive. But if you rank energy use, it is all about managing that conditioned air.

When do scientists have personal control over the energy used in laboratory work?

That depends on what type of laboratory we are talking about. In the heart of pharma, that’s a top-down decision-making process that is taking place in a larger format. In public research funded labs, where principal investigators are doing science that they have been awarded to do, they have a lot of personal control.

Pharma has building meters within those organizations. They have facility folks who work with their Environmental Health and Safety who are tied in with the people in the labs. It’s a common conversation.

Whereas, in PI headed research labs, EHS or other groups in the organization will not know about energy use. We routinely accommodate that situation. I did a plug load study in a research hospital monitoring energy use in benchtop plug-in equipment. Some researchers welcomed the study, while others said that they were in such a critical stage of their science that they couldn’t change anything that might affect my results. I absolutely respect that.

So it’s really on the scientists to step up in academic labs? Is it worth it for scientists to be seeking out the information on their own lab’s airflow?

Yes, it helps everyone to understand where they are in the equation. I never want to interfere with people’s’ work. The question scientists can ask themselves is if there are energy-saving opportunities in a lab that runs 18 air changes an hour 24/7, but is only occupied 8 hours a day. I am able to provide the information to help make every lab a safe, higher-performing space.

What types of lab equipment can qualify for incentives?

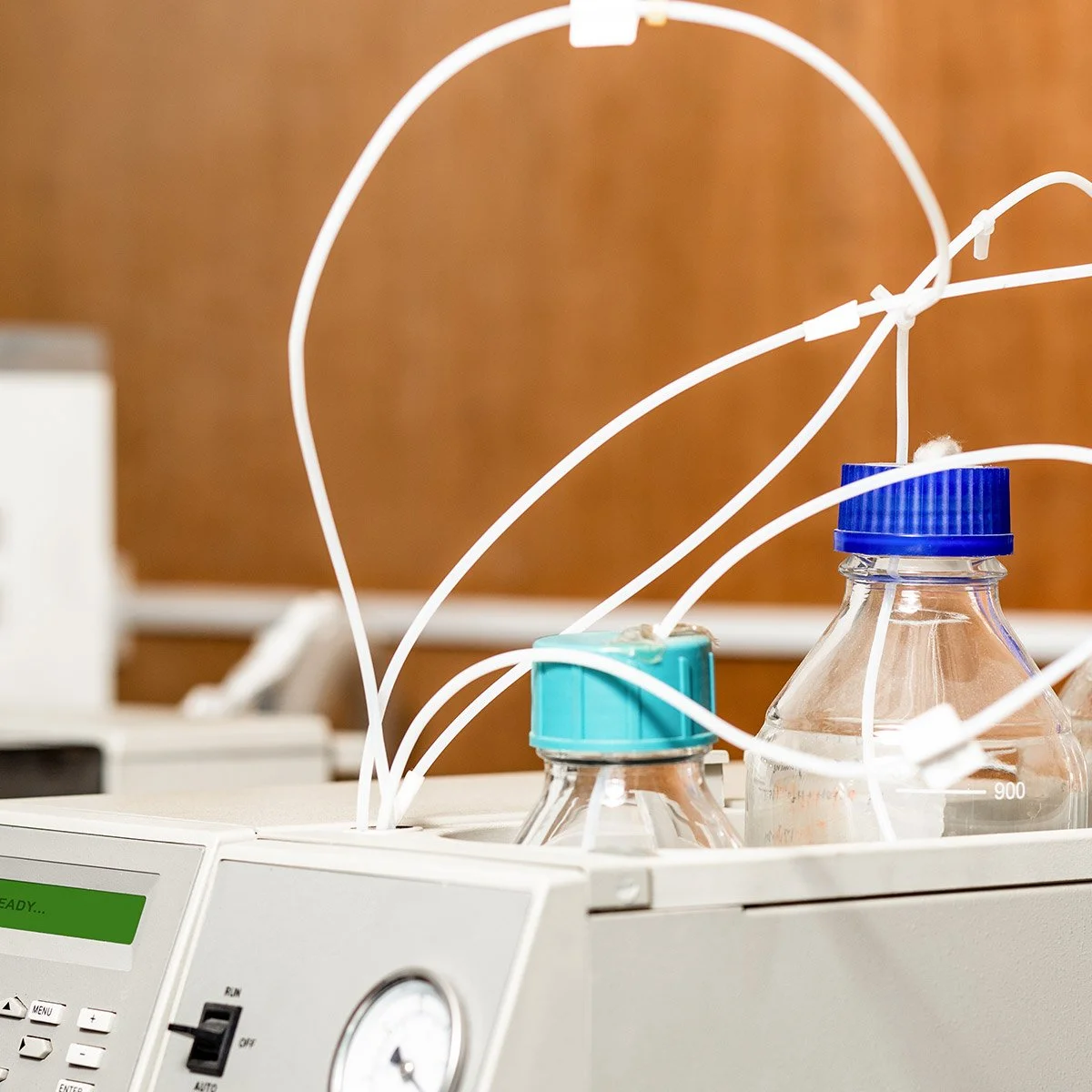

Freezers, biosafety cabinets, ductless fume hoods, autoclaves, incubators, and water sterilization equipment. Effectively, anything using energy that is big, bulky and old!

Is there a good online resource to find energy-efficient lab equipment?

Only recently have energy-efficient freezers become a thing. Thanks to the work done by My Green Lab! There are several online resources to find energy-efficient equipment - although some energy lab equipment is so new it’s not listed yet. The energystar.gov web site has a searchable database for Lab grade refrigerators and Freezers products that are available in the US and Canada. My Green Lab’s ACT label Database has a list of some of the most cutting edge lab equipment in terms of total sustainability. People can contact their local I2SL chapters, who have lists of manufacturer partners who are aligning themselves with what we are doing here. The Green Labs Google Group is a great, organic place where people share ideas.

Could a principal investigator contact you? Should a facility staff member always be included in initial conversations?

Anyone can contact me, especially labs in Massachusetts, Connecticut, and New Hampshire, and if I’m not the right resource, then I can find the right resource to put people on the right path. I often work at the individual lab level. Other times I work with laboratory real estate firms to help them decide what building to target first.

This is a consultative approach. I work with the customer understanding what they want, understanding the requirements, understanding their budget and putting them in touch with the right people to make that happen. I welcome anyone in an organization to contact me to start. For example, I have been called in by P.I.s to talk with lab managers. Maybe they are going to buy a biosafety cabinet or a new freezer, and they want to know how we can help them make those decisions economically. We help them discern the best available equipment from the energy-saving perspective.

Is there any easy way that you have seen an academic lab in an established building successfully reduce their energy consumption?

Shut the sash.

There are fume hood stickers made by the lab sustainability expert Allen Doyle when he was at the University of California. Studies have shown that putting these color-coded stickers on your sash works. It’s simple and cost effective. The sash should be in the green position. The red position is bad.

We quantify the savings from any project they do. We know this works. If a lab wants to do something good today that doesn’t cost them anything, shut the sash.

Are there any energy-saving solutions that also make lab work better for scientists?

Academic scientists directly benefit from working in a lab environment with a better climate. There might be four ULT freezers throwing so much heat, that they need to pull in supplemental cooling to the space. We will provide incentives to allow labs to buy energy star ULT freezers that use 75% less energy than what the lab currently has. You can then get rid of the supplemental cooling system. People can work more comfortably.

In pharma labs, a good example would be automated plug controls to save energy. The outcome of using these systems is a benefit to the scientific workflow. These systems are out there, and they work.

Is Eversource unique as a utility in the United States in how it helps labs?

I believe that we are out front, but I also see how the work that we have done initiated a strong conversation. People in the I2SL national utilities working group with a substantial lab presence in their markets are sharing ideas. I think that we are a little unique. As I look out my window, I see all the cranes, all the people working in buildings in Kendall Square. Here we have thousands and thousands of labs. We need to lead.

Is there a project that you were part of that you are particularly proud of?

Overall I’m proud of the work that we have done to enter the lab market, to peel it back, to understand it. It’s been a three-year process. I’ve had lots of help. People here in Cambridge, in the Boston area, and across the country, who have helped us launch a truly new approach for laboratories.

We have approached it from a product perspective, where if you’re going to buy a piece of equipment, let us know, maybe we can help. From a holistic perspective, in terms of airflow and more complex situations, we’ve tried to figure out where we should be, what companies and strategies we can deploy to make a big lab program successful. And we have done that and that’s meaningful.

I’m particularly proud of the lab freezer project because of the relationship we have with scientists. On my second day on the job, I went to a meeting at Harvard University and I met Quentin Gilly. He asked me what I knew about labs. I said nothing. He asked if I knew Alison Paradise. I said no. He said here’s her number. You call her, tell her that I sent you, ask her what to do, and I did. She said we just received approval for energy star ULT freezers and you should start a program, and we did. We have incentivized 600 freezers since then.

This project has been successful because it was designed to do a couple of things. For us it’s routine. We replace equipment every day. From a lab perspective, we are not messing with science, we are making buildings run a little better and keeping samples a little safer. Yet we now have a relationship with laboratories that we never had before. Scientists rely on us. That’s what I’m most proud of.

If you don’t have Eversource and you’re a PI and you want to make a difference in energy, what can they do?

Start your own green labs program. Green lab programs are popping up all across the country. What I have noticed about I2SL over the years, is that more and more it’s about lab sustainability groups supporting each other. Here in Cambridge, somebody will call me and say, “Hey, I hear what you're doing with Jen at MIT. We just started a green lab group, and six people in my lab are interested. Our first meeting is next Wednesday. Can you come up?”