How does resiliency fit into sustainable laboratory work?

Resiliency is the new focus for laboratory sustainability. The world is relying on the field of life science to rise to the challenge of rapid production of validated Coronavirus tests, therapeutics, and vaccines. The concept of ‘operational resilience’ factors in the ways to keep working in changing conditions. As a biologist, you might think of it as applying the principle of adaptation to your lab work. Today’s blog shares simple and effective ways that you can add resiliency to cold shipping biologicals.

COVID-19 has revealed weak spots in laboratory work that need solutions. Bioscience laboratory work has always relied on a complex supply chain. According to The Wall Street Journal and The New York Times both lab supply chains and lab waste disposal services are now under significant pressure. Organizations are rushing to diversify sources as lab suppliers run low. The "just in time" ordering system for single-use supplies failed up against COVID-19. On the back end, companies that service laboratory waste are processing greater volumes of infectious waste. Adjunctly, there was a lack of recycling capacity before COVID-19 and now the market for rigid plastics, gloves, EPS foam, and film collections is even further restricted. With oil prices at historic lows, we can expect plastic recycling to struggle until new, more economical recycling processes to reuse plastic can reach industrial scale. These bottlenecks in lab supply chains and lab waste services have emphasized the need for sustainable solutions that save time, material, storage, and energy usage in life science.

Adaption to improve life science cold shipping

Cold shipping is a huge contributor to life science waste streams and emissions. New England Biolabs has had a system to take back its customers’ expanded polystyrene (EPS) shippers for reuse and recycling since 1976. After the worldwide recycling crisis hit the entire life sciences community became even more concerned with its responsibility to prevent plastic pollution. NEB resolved to find new ways to help.

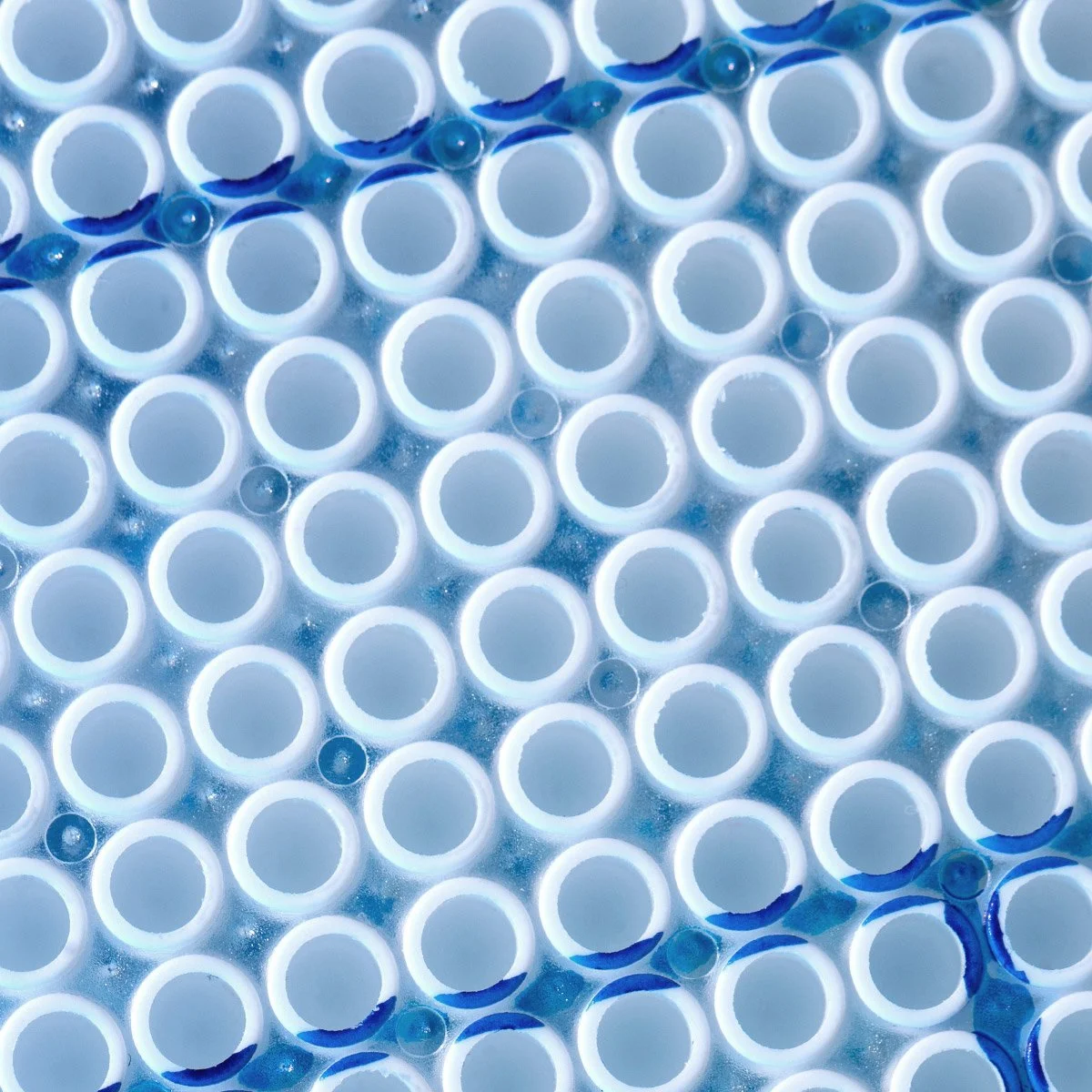

NEB is very proud to have verified the reliability for the Climacell® cooler, a paper-based, fully recyclable and compostable cold shipper, and is starting to transition to utilizing it for shipments in the United States. Climacell was developed by Temperpack, a US company that focuses on providing sustainable solutions for cold chain shipping. (You can learn more about Climacell® cooler in the video below.)

When you receive a paper-based shipper, you eliminate the need to ship back the EPS cooler. This saves your time and storage space in the lab. Considering that your cooler only travels one way, you are also reducing shipping emissions by half. Importantly, you can multiple that effect if you consolidate cold shipment orders.

Scientists can easily add operational resilience to life science cold shipping with the following actions:

Please recycle paper-based coolers.

Please consolidate your lab group orders based on product temperature sensitivity. If your order includes any one item that requires dry ice, i.e. competent E.coli cells, then your entire order will still require an EPS foam shipper.

Please automate consolidation by using your lab supply center, core facility and/or the NEBnow freezer program which has three freezer sizes to match your lab group size.

If you receive an EPS cooler from NEB, you are welcome to use the free mailing label provided to return it to NEB.

The less EPS foam waste needed in life science, the better! More cold shipping options are being tested internationally. For example, NEB as implemented a straw-based cold shipper in Germany. The goal is to develop solutions that “best fit” local waste processing infrastructure.

Stay safe and thank you for being ‘labconscious’!